Buying a new machine only to find it won't connect to your power supply1 is a costly mistake. This leads to frustrating installation2 delays and expensive electrical work before you've even made a single pellet.

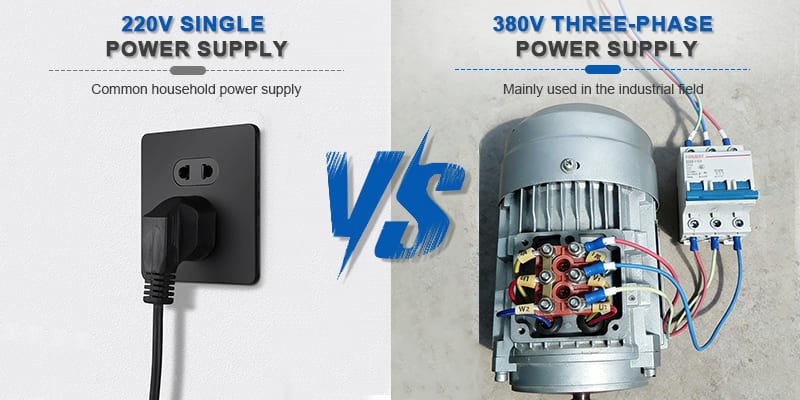

Small, hobbyist-level machines typically use 220V single-phase3 power, which is standard in homes. However, most serious small-scale commercial models4 require or perform better with 380V three-phase5 power due to its efficiency6 and stable power delivery for the motor.

As a procurement manager, making the right infrastructure choice is as critical as selecting the right machine. In my 16 years helping businesses set up production lines, the power supply1 is one of the first things we discuss. It's a foundational decision that impacts everything from initial cost to long-term operational efficiency6. Choosing the wrong one can turn a great investment into a logistical nightmare. The choice isn't just about what's available; it's about matching the machine's capabilities to your production goals, both now and in the future.

When should I choose a 220V single-phase3 machine?

Are you just starting out or testing a new feed formula? Committing to expensive industrial wiring for a small pilot project can seem like an unnecessary financial risk.

A 220V single-phase3 machine is the right choice for very light-duty applications, home use, or initial R&D projects. Its main benefit is convenience, as it can often plug directly into a standard residential power outlet without needing special installation2.

Think of 220V single-phase3 power as the standard electricity you have at home. It’s convenient and readily available. For a machine with a small motor (typically under 4kW), this power supply1 is often sufficient. It allows you to get started quickly without the need to hire an electrician to install a new, dedicated power line. I often see this choice being made by small farm owners making feed for a handful of animals or by brand managers in a lab environment who are simply testing pellet formulations before committing to a larger production run.

The Advantage of Simplicity

The primary draw of a 220V machine is its plug-and-play7 nature. You can often set it up and start producing pellets within hours of delivery. This is perfect for situations where speed and minimal initial investment are the top priorities.

The Limitations of Power

However, this simplicity comes with trade-offs. Single-phase motors are less efficient than their three-phase counterparts. They draw more current for the same power output, which can lead to higher electricity bills8 over time. They also run hotter and can experience more vibrations, potentially shortening the motor's lifespan. You are fundamentally limited in the size and output capacity of the machine you can run on this power source.

Why would I need a 380V three-phase5 model for a small machine?

Is your current machine struggling to keep up as your output needs grow? A machine that constantly overheats or lacks power will bottleneck your entire operation and limit your business's potential.

You need a 380V three-phase5 model for consistent, efficient, and reliable production, even at a smaller scale. Three-phase power delivers smoother, more stable energy, allowing the motor to run cooler, last longer, and handle tougher materials without strain.

If 220V single-phase3 is for convenience, 380V three-phase5 is for professional performance. This is the standard power supply1 in most industrial and commercial settings for a reason. Instead of a single wave of power, three-phase delivers three overlapping waves. This provides a constant, uninterrupted supply of power to the motor. As a procurement manager, you should see this as the choice for long-term reliability and lower operational costs. A machine running on three-phase power is simply more robust. The motor operates with less stress, which is a key factor we consider at STROSEN when designing machines with critical components that are expected to last over 8,000 hours.

The Professional Standard for Efficiency

A three-phase motor is inherently more efficient. It produces more power from less electricity, which translates directly into cost savings on your monthly energy bills. For clients in demanding markets like Germany and the USA, this efficiency6 isn't just a bonus; it's a core requirement for a profitable operation.

| Feature | 220V Single-Phase | 380V Three-Phase |

|---|---|---|

| Best For | Hobbyists, R&D, very small farms. | Small commercial to large scale production. |

| Efficiency | Lower | Higher (Lower energy bills). |

| Motor Lifespan | Shorter (runs hotter) | Longer (runs cooler and smoother). |

| Power Output | Limited, typically under 4kW. | Higher, supports larger and more productive machines. |

| Installation | Simple "Plug and Play". | Requires professional electrical installation2. |

How do I determine which power system is right for my operation?

Making the wrong decision now could force a costly upgrade later. You need a clear framework for choosing a power system that supports both your current needs and your future growth9 plans.

Assess your production volume10, inspect your current electrical infrastructure, and consider your 5-year growth plan. This analysis will tell you if the convenience of 220V outweighs the long-term efficiency6 and power benefits of a 380V system for your specific goals.

Making the right choice is a strategic decision. As a partner to agricultural businesses, this is how I guide clients to make a sound investment. You need to look beyond the machine's price tag and consider the total cost of ownership11 and your business's trajectory. Don't just buy a machine for the business you have today; buy one that can grow with you.

Step 1: Assess Your Production Volume

First, be realistic about your needs. How many kilograms or tons of pellets do you need to produce per hour, day, or week?

- Under 100 kg/hour: A 220V system might be sufficient if you only operate for short periods.

- Over 100 kg/hour: You are entering the realm of commercial production12. A 380V system is highly recommended for the power and reliability needed for continuous operation.

Step 2: Check Your Existing Infrastructure

Next, what power do you already have available?

- Have 380V installed: The choice is easy. Opt for a three-phase machine to leverage the superior power system you already have.

- Only have 220V: Get a quote from a qualified electrician for installing a 380V line. Compare this one-time cost to the long-term benefits of higher efficiency6 and motor longevity. The installation2 cost is often much lower than the cost of a struggling operation.

Step 3: Consider Your Future Growth

Finally, where do you see your operation in five years?

- Stable or hobby-level: A 220V machine might serve you well for years.

- Planning to expand: Investing in a 380V system from the start is the smarter financial move. It provides the foundation you need to scale up your production without having to replace your initial machine or infrastructure.

Conclusion

Choose 220V for convenience in hobbyist settings. For any serious commercial production12, invest in a 380V three-phase5 system for greater efficiency6, reliability, and long-term growth potential.

Discover tips on selecting the best power supply for your machinery needs. ↩

Learn about the installation process and requirements for a 380V power system. ↩

Explore the advantages of 220V single-phase power for home use and small applications. ↩

Find out what makes small-scale commercial models effective for production. ↩

Learn why 380V three-phase power is essential for efficiency in industrial settings. ↩

Understand the importance of efficiency in machinery and its effects on operations. ↩

Discover the benefits of plug-and-play machines for quick setup and use. ↩

Find strategies to minimize electricity costs in your production operations. ↩

Explore the significance of planning for future growth in machinery investments. ↩

Get guidance on evaluating production volume for selecting the right machinery. ↩

Understand the concept of total cost of ownership for better investment decisions. ↩

Understand the characteristics of commercial production in the feed industry. ↩