Using the wrong raw material can jam your machine and ruin your pellets. This leads to costly downtime, wasted ingredients, and frustration, directly impacting your production targets.

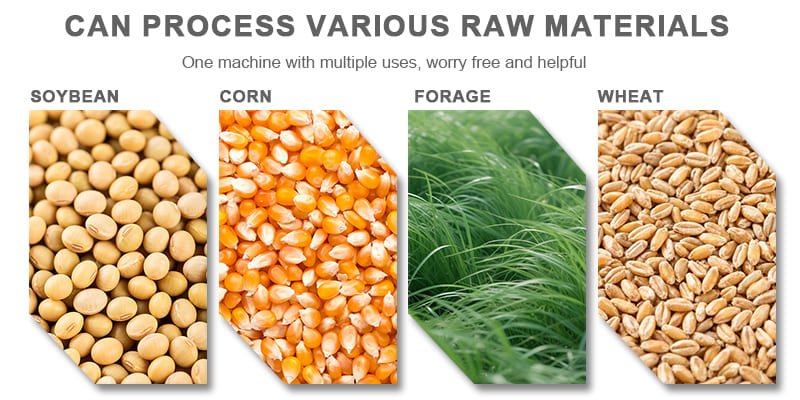

Yes, a feed pellet machine1 can process a wide variety of materials, including common ingredients like corn2, soybean meal3, and grass4. The key to success is proper preparation, especially grinding materials5 to a consistent size and controlling the moisture content6 to ensure high-quality pellets.

As a procurement manager, your goal is to maximize the value of your assets. That means knowing exactly what your equipment can and can't do. I've spent over two decades in the agricultural machinery industry, and one of the most common questions I get is about material compatibility. A pellet machine is an incredibly versatile tool, but it's not magic. It works as part of a system. Understanding how to prepare your raw materials is just as important as choosing the right machine. Let's explore the different types of materials you can use and the simple steps needed to get them ready.

What types of grain and protein sources7 can be used?

You have access to various grains but are not sure if they are suitable. Guessing the right mix can lead to pellets that lack the nutritional value8 your animals need.

Grains like corn2, wheat, barley, and rice, along with protein sources7 such as soybean meal3, sunflower cake, and fish meal, are ideal for making feed pellets. These ingredients form the core of most feed formulas, providing essential energy and protein for healthy animal growth.

Grains and protein meals are the building blocks of animal nutrition. Almost every commercial feed formula is based on these components, and your own production should be no different. For a large-scale operation, using these common ingredients ensures a consistent and nutritionally complete product. Our STROSEN machines are specifically engineered to handle the density and characteristics of these materials, ensuring efficient, high-volume production. Before any material enters the pellet mill, it needs to be ground into a fine, consistent powder. This increases the surface area, allowing for better moisture absorption and heat penetration during the pelleting process9, which results in a more durable and digestible pellet.

Grains for Energy

Grains are the primary source of carbohydrates, which provide the energy animals need. Corn is the most popular choice due to its high energy content10 and good binding properties.

Protein for Growth

Protein is essential for muscle development and overall health. Soybean meal is the industry standard, but other options work just as well.

| Raw Material | Primary Nutrient | Key Considerations for Pelleting |

|---|---|---|

| Corn | Energy (Starch) | Excellent binder, one of the easiest materials to pellet. |

| Soybean Meal | Protein | The most common protein source; must be mixed well. |

| Wheat | Energy & Protein | High gluten content can create very durable pellets. |

| Fish Meal | High-Quality Protein | Adds essential amino acids and oils, good for young animals. |

Using the right mix of these materials allows you to create a complete feed that meets the exact nutritional standards11 required by your operation.

Can fibrous materials12 like grass4 and alfalfa be processed?

You have abundant fibrous materials12 like grass4 or crop stalks. Thinking they are useless waste hurts your bottom line when they could be a valuable feed source for your business.

Yes, fibrous materials12 like grass4, hay, alfalfa, and agricultural residues13 like straw can be processed. These typically require more thorough pre-treatment, such as fine chopping and moisture adjustment, to create durable pellets. Flat die machines are often excellent for these low-density materials.

For any procurement manager focused on cost reduction, this is where things get interesting. Turning agricultural by-products into valuable feed is a huge opportunity to improve profitability. Materials like grass4, alfalfa, and even corn2 stalks are often seen as waste, but with the right equipment, they become a low-cost ingredient source. The main challenge with fibrous materials12 is their low density and natural elasticity, which can make them harder to compress into a solid pellet. This is why preparation is so critical.

The Challenge of Fiber

Fiber is tough. To make a good pellet, you first need to break it down. This usually involves chopping or grinding the material into very short pieces, typically less than the diameter of the holes in your pellet die. Some flat die pellet machines are specifically designed with higher pressure to handle these materials effectively. Sometimes, mixing fibrous materials12 with a grain like corn2 can also help with binding.

Turning Waste into Value

The economic case is clear. If you can take a material that you would otherwise pay to dispose of and turn it into feed, you have created value out of thin air. This is a core principle of an efficient agricultural operation. Our experience with clients in diverse markets like Kenya and Iraq has shown that the ability to process local biomass is a significant competitive advantage. It reduces reliance on imported ingredients and lowers overall feed costs dramatically.

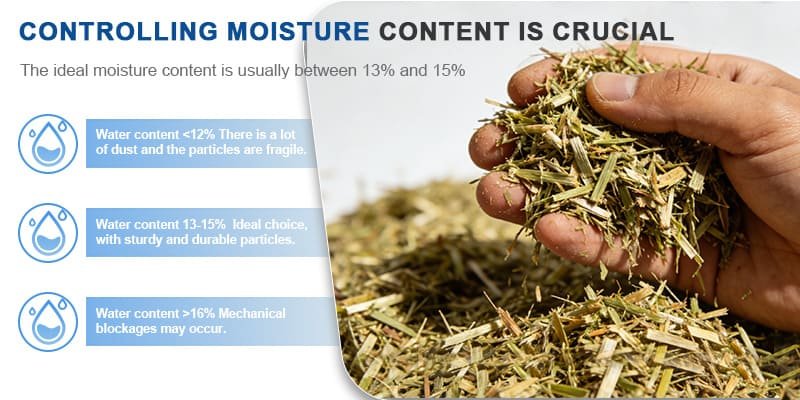

Why is controlling moisture content6 so important?

Your pellets are either crumbling apart or your machine is constantly jamming. This inefficiency creates massive waste, slows down production, and threatens your deadlines and your profit margins.

Controlling moisture is the most critical factor for successful pelleting. The ideal moisture content6 is typically 13-15%. It acts as a lubricant for the machine and a binder for the pellet. Too little moisture causes friction and breakage; too much causes clogging.

In all my years, I have seen more production problems caused by incorrect moisture levels than by any other single factor. It's the secret ingredient that many people overlook. When raw material is compressed under the immense pressure and heat inside the die, the moisture turns into steam. This steam helps to cook and gelatinize the starches in the feed, which acts as a natural glue to bind the pellet together. Getting the moisture right ensures smooth operation and a high-quality finished product.

The Science of Perfect Pellets

It's a delicate balance. If your material is too dry, the friction inside the die increases dramatically. This leads to higher energy consumption, accelerated wear on your die and rollers, and pellets that are brittle and fall apart. If the material is too wet, it becomes mushy. It will slip against the rollers instead of being forced through the die, leading to blockages and inconsistent, soft pellets that are prone to mold.

| Moisture Level | Result | What You Should Do |

|---|---|---|

| Below 12% | Dusty, crumbly pellets; high machine wear. | Add a small amount of water or steam during mixing. |

| 13-15% | Ideal. Strong, durable, high-quality pellets. | Maintain this level consistently. |

| Above 16% | Machine clogging; soft, mushy pellets. | Dry the raw material before processing. |

Our STROSEN machines are built to withstand the pressures of continuous production, but they perform best when the raw materials are properly prepared. Ensuring your feed mix is within this optimal moisture range will maximize your machine's performance and lifespan.

Conclusion

Feed pellet machines can process a vast range of materials, from grains to grass4. Success depends on proper preparation: grinding for size and, most importantly, managing moisture content6 for optimal results.

Understanding the mechanics of a feed pellet machine can help you optimize its use for various materials. ↩

Explore how corn serves as a primary ingredient in feed pellets, enhancing energy content. ↩

Learn about the nutritional benefits of soybean meal and its role in animal growth. ↩

Discover the methods to effectively utilize grass as a valuable feed source. ↩

Find out how grinding affects the quality and efficiency of feed pellet production. ↩

Understanding moisture control can significantly improve pellet quality and machine performance. ↩

Learn about various protein sources and their importance in animal nutrition. ↩

Learn how the right ingredients in feed pellets meet the nutritional needs of livestock. ↩

A detailed look at the pelleting process can help you achieve better results. ↩

Explore how energy content varies among feed ingredients and its impact on animal growth. ↩

Learn about the nutritional standards that should be met for healthy animal growth. ↩

Explore the potential of fibrous materials like alfalfa in enhancing feed nutrition. ↩

Discover innovative ways to utilize agricultural waste for cost-effective feed solutions. ↩