Your machine is jamming and your pellets are crumbling. This operational chaos costs you money, wastes raw materials1, and jeopardizes your entire production schedule2, hitting your bottom line hard.

The ideal moisture content3 for most raw materials1 is between 13-15%. This level is crucial because it acts as both a lubricant during compression and a natural binder for the final pellet. Getting this right ensures smooth machine operation and a durable, high-quality product.

As a procurement manager with over 16 years of experience in agricultural machinery, I can tell you that moisture is the single most overlooked factor in pellet production4. It truly is the 'secret ingredient' that determines success or failure. The intense pressure and heat inside the die turn this moisture into steam, which cooks the starches in the feed and naturally binds the pellet together. But it's a very delicate balance. Getting it wrong leads to serious problems, but getting it right is the key to efficiency. Let's look at what happens at both extremes and how you can get it right, every time.

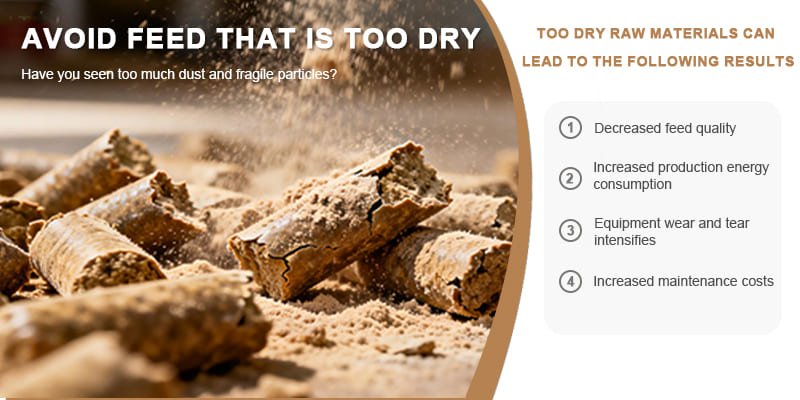

What happens if my raw materials1 are too dry?

Are you seeing excessive dust and brittle pellets that break easily? This isn't just waste; it’s a clear sign that you're putting severe strain on your expensive machinery.

When moisture content3 is below 12%, friction inside the pellet die skyrockets. This causes poor-quality, dusty pellets, increases power consumption, and leads to premature wear and tear on critical components like your die and rollers, driving up your maintenance costs.

When raw material is too dry, it lacks the lubrication needed to pass smoothly through the die holes. Instead of a fluid compression process5, you get a grinding, high-friction battle. This extreme friction generates excessive heat, which can scorch the nutrients in your feed, reducing its quality. Even worse, it puts immense physical stress on the heart of your machine: the roller and die. I've seen dies that should have lasted for 8,000 hours fail in a fraction of that time due to operators consistently using overly dry materials.

The True Cost of 'Dry' Production

This isn't just a quality issue; it's a financial one that directly impacts a procurement manager's budget. Higher friction means your machine's motor must work harder, leading to a noticeable increase in your electricity bill. The accelerated wear on your rollers and die means you'll be ordering replacement parts far more frequently, adding to your operational and procurement costs. While our STROSEN machines are built with high-quality alloy steel for maximum durability, even the toughest equipment will suffer under improper operating conditions.

| Problem | Cause | Direct Financial Impact |

|---|---|---|

| Brittle Pellets | Poor gelatinization | Increased product waste ("fines"). |

| High Energy Use | Increased friction | Higher electricity bills per ton produced. |

| Fast Die Wear | Metal-on-metal friction | Frequent replacement costs and downtime. |

What if my raw materials1 are too wet?

Is your pellet mill constantly shutting down from blockages? The pellets that do come out are soft and mushy, bringing your entire production line to a grinding halt.

If moisture exceeds 16%, the material becomes too slippery to be properly compressed by the rollers. This leads to blockages inside the die. Any pellets produced will be soft, inconsistent, and have a short shelf-life due to the high risk of mold.

Excess moisture creates a completely different, but equally frustrating, set of problems. Instead of being forced through the die holes, the wet material simply slips and slides against the roller surface. The pressure required for compression is never achieved. The material quickly builds up, creating a solid plug inside the die, which jams the machine and forces a complete stop. As a manager, this means unscheduled downtime, labor costs for cleaning the blockage, and a major disruption to your production schedule2. This is a common challenge for our clients in humid regions, and it underscores the need for proper raw material preparation.

The Hidden Dangers of Damp Material

Even if you manage to produce some pellets, their quality will be severely compromised. They will be soft, easily squashed, and will not withstand transport. More critically, the high moisture content3 creates the perfect breeding ground for mold and fungi. This not only spoils the feed but can also lead to the development of mycotoxins6—toxic substances that are incredibly harmful to animals. This poses a significant risk to your brand's reputation and can lead to costly liability issues. A reliable production line is a safe production line.

How can I accurately measure and adjust moisture content3?

You know moisture is the key, but how can you be sure you've got it right? Guessing is a recipe for disaster, leading to the same frustrating production problems from both ends.

Use a digital moisture meter for a quick and accurate reading. To increase moisture, spray a fine mist of water during mixing. To decrease it, spread the material in a thin layer to air-dry7, or use a dedicated rotary dryer8 for large volumes.

Consistency in a large-scale operation demands accurate measurement. Guesswork is not a scalable or reliable strategy. Investing in a simple digital moisture meter is one of the best decisions a production facility can make. It removes all doubt and provides instant, actionable data. You simply insert the probe into the ground raw material and get a precise reading in seconds.

Professional Method: Digital Testers

For any commercial operation, a digital meter is essential. It's the only way to guarantee you are consistently hitting that ideal 13-15% range. This consistency reduces operational risk and is a cornerstone of any ISO 9001-compliant quality management system9.

The 'Hand Squeeze' Method

If you're in a pinch, you can use a traditional field test. Grab a handful of the ground material and squeeze it tightly. If it holds its shape when you open your hand but crumbles easily when you poke it, the moisture is likely in the correct range. If it falls apart immediately, it's too dry. If it stays in a dense, wet clump, it's too wet. While useful, this should only be a backup to a proper digital meter.

| Action Needed | Method for Small Scale | Method for Large Scale (recommended) |

|---|---|---|

| Increase Moisture | Use a spray bottle during mixing. | Integrate a water/steam addition system into your mixer. |

| Decrease Moisture | Spread material on a clean floor to air-dry7. | Use a dedicated rotary drum dryer before the pelleting stage. |

As a provider of one-stop solutions, we at STROSEN can help you integrate these pre-treatment systems into your production line.

Conclusion

Mastering the 13-15% moisture range is the key to pellet quality. It prevents jamming, ensures durability, and protects your machinery, guaranteeing an efficient and profitable operation from start to finish.

Exploring the impact of raw materials on pellet quality can help optimize production processes. ↩

Optimizing your production schedule can lead to increased efficiency and reduced downtime. ↩

Understanding the ideal moisture content is crucial for ensuring high-quality pellets and efficient production. ↩

Learning best practices in pellet production can enhance efficiency and product quality. ↩

Understanding the compression process is key to producing high-quality pellets. ↩

Learning about mycotoxins is crucial for ensuring the safety and quality of animal feed. ↩

Effective air-drying methods can help maintain the quality of raw materials before processing. ↩

Exploring rotary dryers can reveal efficient ways to manage moisture levels in raw materials. ↩

Understanding ISO 9001 can help improve quality assurance in pellet production. ↩