Your feed pellet machine1 is a crucial part of your farm, but unexpected breakdowns can be a real headache. This downtime wastes time, money, and stops your production dead.

To keep your machine running perfectly, focus on three key areas: regular lubrication2 with the correct grease and gear oil, using a dedicated air switch3 for electrical safety4, and performing routine checks on core components5 like the pressure rollers6. This proactive approach prevents most common problems.

Knowing the basics is a great start. But let's get into the specific details that will turn your machine into a reliable workhorse for years to come. I've seen it all in my 25 years in this business, and I want to share what I know works. Let’s dive deeper into the practical steps you can take today.

How Can You Get the Perfect Pellet Size and Proper Lubrication from Day One?

Getting inconsistent pellets or skipping the initial setup can be frustrating. This leads to wasted feed7 and can put stress on the brand-new gearbox before you even get started.

You can easily adjust pellet length using the built-in cutter. For vital lubrication8, fill the gearbox through the oil port with 85W/90 heavy-duty gear oil[^9]. This simple step is critical for cooling the gearbox and ensuring it runs smoothly from the very first use.

This part is about getting the fundamentals right. At STROSEN, we design our machines like the 160 model to be user-friendly, but these first steps are non-negotiable for performance.

Fine-Tuning Your Pellet Length

The cutter device on your machine isn't complicated. It's a simple, adjustable mechanism that lets you control how long or short the final pellets are. This is great because you can customize the feed for different animals, whether you're feeding poultry or small livestock. A quick adjustment here makes a big difference in feed consistency.

Gearbox Oil: The Machine's Lifeblood

Think of the gearbox as the heart of your machine. It needs the right oil to function. We specifically recommend 85W/90 heavy-duty gear oil because it does two things perfectly: it lubricates all the moving parts to reduce friction and it helps dissipate heat. A cool, well-lubricated gearbox is a happy, long-lasting gearbox.

| Action | Result of Proper Care | Consequence of Neglect |

|---|---|---|

| Adding Gear Oil | Smooth, cool operation; extended gearbox life. | Overheating, friction, premature gear failure. |

| Adjusting Cutter | Consistent, desired pellet size for your animals. | Wasted feed, inconsistent product quality. |

What are the Absolute Must-Know Rules for Powering Your Machine Safely?

Plugging in a new machine seems easy. But using a standard wall outlet is a huge mistake that can cause overloads, burn out the motor, or even create a fire hazard.

To power your 220V machine, you must use a dedicated air switch3, not a regular socket. This is a special circuit breaker that can handle the high electrical load. After connecting, always check the current and voltage to make sure the power supply is stable.

Electrical safety is not something to take lightly. I've seen too many machines fail because of improper wiring. It’s an expensive mistake that is very easy to avoid if you just follow a couple of simple rules for your STORSEN 160.

Why a Dedicated Air Switch is Crucial

Let's be clear: a standard wall socket is designed for household appliances, not powerful machinery. Your feed pellet machine1 draws a significant amount of current when it starts up and runs. An air switch is basically a heavy-duty circuit breaker. It’s built to handle this load and will trip to cut the power if there’s a dangerous surge, protecting both you and your equipment.

Monitoring Your Power

Once you're connected correctly, take a moment to monitor the power. This quick check confirms that your wiring is solid and your power source is stable. Unstable voltage can put a lot of strain on the motor over time, leading to a shorter lifespan. A stable connection means a healthy machine.

| Connection Type | Safety Feature | Risk Level |

|---|---|---|

| Dedicated Air Switch | Protects against overcurrent and surges. | Low |

| Standard Wall Outlet | No protection for high loads. | High (Fire, motor damage) |

How Do You Maintain the Hardest-Working Part of Your Machine?

The pressure rollers6 and bearings are the core of your machine. If they are poorly adjusted or run dry without grease, you'll get bad pellets and eventually face a costly bearing failure.

Routinely inspect the pressure rollers6 to ensure they spin evenly. The key to their longevity is lubrication8. Regularly add grease through the machine's grease nipples and directly to the bearings by temporarily removing the lock nut. This simple act prevents wear and tear.

The pressure system is where the magic happens. It takes raw material and presses it into perfect pellets. Giving this system a little attention goes a long way. After 25 years of manufacturing these machines, I can tell you that 90% of major failures could have been prevented with basic lubrication8.

Checking and Adjusting the Pressure Rollers

You don't need to be a mechanic to do this. Just check if the rollers are turning smoothly and seem to be applying even pressure. If one side is working harder than the other, you can use the pressure adjustment screws9 to even things out. This ensures consistent pellet quality and prevents uneven wear on the parts.

A Simple Greasing Guide

There are two places to add grease. First, the easy-to-spot grease nipples on the machine's body. A few pumps of grease here on a regular schedule keep things moving. For more thorough, long-term care, you'll want to lubricate the bearings directly. To do this, you just need to unscrew the lock nut on the roller shaft, add grease, and tighten it back up. This protects the bearings from heat and friction.

What is the Real Secret to Making Your Pellet Machine Last for Years?

You bought your machine to be a reliable, long-term tool. However, just waiting for something to break is a reactive approach that leads to stress and expensive downtime.

The secret is a proactive mindset summed up by the "30/70" rule: spend 30% of your time using the machine and 70% maintaining it. This includes one major task: changing the gear oil completely after the first 1-1.5 years of use for a new machine.

This philosophy might sound like a lot of work, but it's actually the opposite. It saves you work in the long run. A few minutes of checks and lubrication8 each week is far better than losing a whole day to a major repair. It's about preventing problems before they start. It's how we ensure quality at STROSEN, and it's how you can ensure reliability at home.

Your First Big Service: Changing the Gear Oil

After about a year to a year and a half of use, your new machine is due for its first full gear oil change. This is critical for getting rid of any small metal particles from the break-in period.

- Drain: Locate the drain plug at the bottom of the gearbox and let all the old oil out.

- Refill: Find the filling port, which is marked with a yellow label.

- Measure: Add about 5 liters of fresh 85W/90 heavy-duty gear oil.

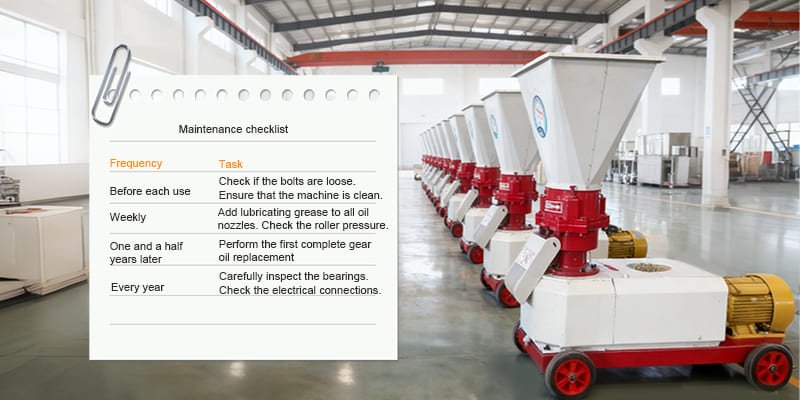

Your Maintenance Checklist

Embracing the "3-parts use, 7-parts maintenance" rule is easy with a schedule.

| Frequency | Task |

|---|---|

| Before Each Use | Check for loose bolts. Ensure the machine is clean. |

| Weekly | Add grease to all grease nipples. Check roller pressure. |

| After 1.5 Years | Perform the first full gear oil change. |

| Annually | Inspect bearings more closely. Check electrical connections. |

Conclusion

Proper maintenance boils down to three things: consistent lubrication8, safe electrical practices, and proactive care. Follow these steps, and your STROSEN feed pellet machine1 will serve you reliably for years.

Discover the essential features that make a feed pellet machine effective and efficient. ↩

Understanding the importance of regular lubrication can enhance your machine's performance and longevity. ↩

Learn how a dedicated air switch can protect your equipment and ensure safe operation. ↩

Explore essential electrical safety practices to prevent accidents and equipment damage. ↩

Understanding core components can help you identify maintenance needs and improve performance. ↩

Discover the critical role pressure rollers play in producing high-quality feed pellets. ↩

Learn strategies to reduce feed waste and improve your production efficiency. ↩

Explore effective lubrication practices to keep your machinery running smoothly. ↩

Understanding pressure adjustment screws can help you maintain consistent pellet quality. ↩