Struggling with inconsistent feed quality and rising costs? You need a reliable production solution you can control, but finding the right machine supplier is tough and full of risks.

Sourcing a reliable cattle feed pellet mill1 means partnering with an experienced OEM/ODM manufacturer2. Look for a supplier with extensive quality control3, international certifications like ISO 90014 and CE, and proven experience in customizing machines for global markets to ensure durability, performance, and brand integrity.

I speak with procurement managers from all over the world, and their biggest concern isn't just the price of a machine. It's the hidden costs of failure: downtime, repairs, and a damaged brand reputation. They're looking for a partner, not just a product. Let’s break down what truly matters when choosing a manufacturing partner to build your line of cattle feed equipment. It's about finding a foundation you can build your brand on for years to come.

What Makes a Pellet Mill Truly High-Quality?

Tired of seeing equipment fail long before its time? The constant maintenance and performance drops eat into your profits and hurt your brand's credibility. It's frustrating when a machine looks good on paper but doesn't last.

A high-quality pellet mill uses superior raw materials like high-grade alloy steel for core components. It undergoes precise manufacturing processes, including heat treatment, and passes strict performance tests for efficiency and durability, all verified by international standards like ISO 90014 and CE.

I remember a conversation with a new client from Russia. He was a brand manager who was tired of dealing with warranty claims. His previous supplier's machines were failing because the rollers and dies wore out in less than a year. He came to us looking for a solution that would last. At our company, STROSEN, we believe quality isn’t just a final check; it's built-in from the very beginning. It comes down to three key areas: the materials we use, the way we build, and the tests we run.

The Foundation: Raw Materials and Core Components

The heart of any pellet mill is the die and roller system. This is where all the pressure and friction happens. That's why we don't cut corners here. We use high-grade alloy steel5 and robust cast iron for these parts. They undergo a specific heat treatment process that hardens the material, making it incredibly resistant to wear and tear. This means our machines' key components can run for over 8,000 hours, which is a game-changer for large-scale operations that can't afford downtime.

The Process: Advanced Manufacturing and Quality Control

A great design with poor execution is a failed product. Our factory has five dedicated production lines, and each one is overseen by a quality control3 manager with at least eight years of experience in agricultural machinery6. They supervise everything from the precision of the welds to the application of the anti-corrosion surface coatings. This hands-on approach, all managed under an ISO 90014 system, ensures that every single machine that leaves our factory meets the exact same high standard.

The Proof: Rigorous Testing Protocols

We don't just hope our machines work well; we prove it. Before any machine is shipped, it goes through a series of tests to guarantee performance. We run it under full load to test its strength, we measure its vibration to ensure stability, and we even simulate different environmental conditions.

| Test Type | Purpose | STROSEN Standard |

|---|---|---|

| Efficiency Test | Measures pellet output versus energy input. | Achieves over 30% higher efficiency. |

| Durability Test | Simulates long-term use on key components. | Key parts exceed 8,000-hour lifespan. |

| Load Test | Runs the machine at maximum capacity. | Confirms structural integrity and power. |

| Fuel/Energy Test | Measures consumption under normal operation. | Reduces consumption by up to 20%. |

This level of testing gives our partners confidence. They know the machine they put their brand name on has been pushed to its limits and is ready for the real world.

How Can Customization Meet Your Specific Market Needs?

Does a generic, one-size-fits-all machine fail to solve your customers' actual problems? You might be missing key opportunities because the equipment isn't adapted to the local power supply, feed ingredients, or scale of operation.

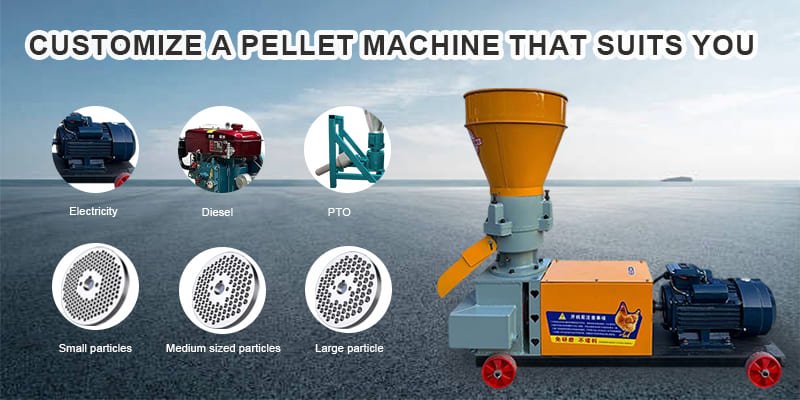

True customization adapts a machine's core features to your market. This includes offering different power sources (electric, diesel, PTO), die sizes for specific cattle needs (calves, dairy, beef), and production capacities7. A strong OEM partner helps you design the perfect solution for your customers.

A few years ago, we started working with a large distributor in Kenya. Their customers are a mix of small family farms and larger agricultural cooperatives. A single machine model wasn't going to work. The small farms had no access to three-phase electricity, while the cooperatives needed much higher output. This is where our role as an OEM/ODM partner really shines. We don't just sell machines; we co-create solutions. We worked with them to develop two distinct models for their brand, one small diesel-powered unit8 and a larger PTO-driven one for the co-ops.

Matching Power to Your Customer's Environment

The first question we always ask a new partner is, "What does your customer's farm look like?" The answer determines the power source. In developed regions like Germany or parts of the US, a powerful electric motor is perfect. But in many emerging markets across Africa or along the "Belt and Road," a reliable diesel engine or a PTO (Power Take-Off) attachment for a tractor is the only practical option. Offering this flexibility allows your brand to serve a much wider market.

Tailoring Feed Output for Different Cattle Types

Cattle nutrition is not one-size-fits-all, and your machine shouldn't be either. The ideal pellet size9 and formula change based on the animal's age and purpose. We help our partners select the right die aperture and compression ratio to produce pellets optimized for different needs.

| Cattle Type | Nutritional Focus | Recommended Pellet Diameter |

|---|---|---|

| Calves | High protein, easy to digest | 4-5 mm |

| Beef Cattle | High energy for fattening | 6-8 mm |

| Dairy Cows | Balanced protein and fiber for milk | 6-8 mm |

By providing machines that can be easily fitted with different dies, you empower your customers to produce scientifically-formulated, balanced feed. This directly improves their herd's health and productivity, which in turn builds immense loyalty to your brand.

Scaling Production from Farm to Factory

Your brand might serve customers ranging from a farmer with 50 head of cattle to a commercial feed plant producing tons per day. We can support that entire range. For smaller operations, our flat die pellet mills10 are perfect. They are simple, robust, and cost-effective. For large-scale commercial production, we manufacture ring die pellet mills11, which offer continuous, high-volume output. As an OEM partner, we can provide you with a full product portfolio under your brand, allowing you to be a one-stop-shop for your customers.

Why is an OEM/ODM Partnership Better Than Just Buying Off-the-Shelf?

Are you just buying and reselling machines, or are you building a lasting brand? Off-the-shelf products put you in a price war with countless other resellers, offering no unique advantage. A true partnership changes the game.

An OEM/ODM partnership gives you a one-stop solution from product design to mass production. It ensures your product is unique, meets strict international standards, has a reliable supply chain12, and ultimately lowers your risks while building brand equity13 that you own.

I've seen so many brand managers get stuck in the cycle of sourcing the cheapest machine, only to spend a fortune on customer support14 and warranty replacements. It's a short-term strategy that can destroy a brand's reputation. An OEM/ODM partner like STROSEN fundamentally changes this dynamic. You are not just a customer; you are a partner in the design and manufacturing process. We are invested in your success because your brand's growth is our growth.

Long-Term Risk Reduction

When you buy an off-the-shelf product from a trader, you have no visibility into the supply chain12, the quality of the components, or the consistency of production. With an OEM partnership, you eliminate these risks. Our ISO 90014-certified process means every component is traceable and every machine is built to a consistent, documented standard. I once worked with a procurement manager for a major U.S. brand who calculated that by partnering with us, he reduced his projected warranty costs by over 70% in the first two years alone. That's the power of controlled quality.

Building Your Brand's Reputation

A partnership allows you to build a product that is uniquely yours. We work with your team to design a machine that not only performs to your specifications but also reflects your brand's identity. When your customers have a great experience with a durable, efficient, and reliable machine that carries your name, they become your best advocates. You are no longer competing on price; you are competing on quality and trust, which is a much more profitable place to be.

The STROSEN Advantage: A One-Stop Solution

With 25 years of experience, we've refined our process to make it seamless for our partners. We handle everything from the initial design consultation to full-scale production and quality assurance, all the way to global logistics.

| Feature | Off-the-Shelf Purchase | STROSEN OEM/ODM Partnership |

|---|---|---|

| Product Design | Generic, no control | Fully customizable to your brand |

| Quality Control | Unknown, inconsistent | ISO 90014 certified, full testing |

| Brand Building | None, you are a reseller | You own the brand equity13 |

| Supply Chain | Unstable, no visibility | Secure and consistent |

| Long-Term Support | Limited, transaction-based | Partnership-focused for growth |

| Market Exclusivity | No | Possible through custom design |

Our mission is simple: "We will realize your ideas!" We provide the manufacturing expertise so you can focus on building your brand and serving your customers around the world.

Conclusion

Partnering with the right OEM manufacturer is the key to sourcing high-quality, customized cattle feed pellet mill1s. It helps you reduce risk and build a trusted global agricultural brand.

Explore this link to discover top-rated cattle feed pellet mills that ensure quality and efficiency. ↩

Learn about the benefits of partnering with an OEM/ODM manufacturer for your production needs. ↩

Find out how quality control can enhance product reliability and customer satisfaction. ↩

Understand the significance of ISO 9001 certification in ensuring product quality and reliability. ↩

Discover why high-grade alloy steel is crucial for durability and performance in machinery. ↩

Stay updated on the latest innovations and trends in agricultural machinery. ↩

Learn about the various production capacities available for pellet mills to suit different needs. ↩

Discover the benefits of diesel-powered units for agricultural operations in remote areas. ↩

Explore the impact of pellet size on cattle nutrition and overall health. ↩

Explore the uses and advantages of flat die pellet mills for small operations. ↩

Discover the features and benefits of ring die pellet mills for large-scale production. ↩

Discover effective supply chain management strategies to ensure product quality and availability. ↩

Learn how to build brand equity through quality products and customer satisfaction. ↩

Explore the role of customer support in maintaining a positive brand reputation. ↩