Struggling to find a reliable feed source? Unstable prices and quality are hurting your profits. A small feed pellet mill1 gives you complete control over your animal nutrition and costs.

The best small animal feed pellet mill depends on your needs. You should consider your raw materials2, required output, and power source3. For most farms, a die-turning (D-type) electric mill offers a great balance of cost and efficiency for producing high-quality feed pellets.

I remember a client from Kenya, a procurement manager for a large agricultural cooperative. He was tired of the fluctuating quality and price of commercially available feed. His cooperative needed a solution that was reliable and put them in control. Finding the right machine felt like a huge task, but by breaking it down, we found the perfect fit for his operations. Let's walk through the same process I used with him, so you can make a confident decision for your business.

Why Should You Choose a Small Feed Pellet Machine?

Are manual feed preparations4 eating up your time and labor? This inefficiency costs you money and limits your farm's growth potential. A small machine automates this process, saving you labor.

A small feed pellet machine is perfect for small to medium-scale operations. It offers cost-effectiveness, fresh feed on demand, and full control over ingredients. This leads to healthier animals and better operational efficiency, making it a smart investment for farms and cooperatives.

When you run a farm or manage procurement for one, every dollar and every hour counts. Relying on outside suppliers for feed can introduce uncertainty. Prices change, quality varies, and supply chains can be disrupted. Investing in a small feed pellet machine brings produção in-house, giving you three main advantages.

Better Nutrition, Better Growth

You know your animals best. With your own mill, you can create custom feed formulas5 using locally available ingredients. This means you control the nutritional content6 completely, ensuring your livestock, poultry, or fish get the exact diet they need for optimal health and growth. You are no longer guessing what fillers are in your commercial feed.

Significant Cost Reduction

Bagged feed is expensive because you're paying for someone else's labor, processing, and transportation. By making your own pellets, you cut out the middleman. You can buy raw materials2 in bulk when prices are low and produce feed as needed. In my 25 years of experience, I've seen our clients reduce their feed costs by over 30% after switching to in-house production.

Operational Independence

A small feed mill makes you self-sufficient. You're not at the mercy of a supplier's stock or delivery schedule. This independence is critical, especially for businesses in remote areas or those, like my clients in Russia and Iraq, who face logistical challenges. You produce what you need, when you need it.

| Feature | Manual Feed Mixing | Using a Pellet Mill |

|---|---|---|

| Labor Cost | High, time-consuming | Low, automated process |

| Nutrient Consistency | Low, hard to mix evenly | High, uniform pellets |

| Feed Storage | Difficult, separates easily | Easy, compact and durable |

| Animal Digestion | Less efficient | More efficient due to gelatinization |

What Can You Make with a Small Feed Mill?

Worried a new machine won't handle your specific feed ingredients? Committing to equipment that isn't versatile is a big risk. Our mills are designed for flexibility7 to handle your unique needs.

A small feed mill processes a wide range of materials like corn, wheat, soybean meal, grass, and alfalfa. It produces customized feed pellets for various animals, including poultry (chickens, ducks), livestock (cattle, pigs, sheep), and even aquatic animals like fish.

The beauty of a feed pellet mill is its versatility. You are no longer limited to standard feed formulas. I worked with a cooperative in Australia that needed to incorporate a specific type of local grass into their sheep feed to improve wool quality. We helped them select a machine and die-set that could process this fibrous material efficiently. The machine should adapt to you, not the other way around.

Wide Range of Raw Materials

Our machines are built to handle the ingredients you have available. This can be anything from common grains to more specialized additives. You can create a balanced diet that is both effective and affordable. We ensure our rollers and dies are made from high-strength alloy steel8 to handle this variety without failing.

Feed for All Your Animals

Whether you are raising a single type of animal or have a diverse farm, one machine can often do it all. By simply changing the formula and the die, you can switch from making chicken feed to pig feed to fish feed. The key is in the pellet diameter and length, which our machines allow you to control.

Here is a simple breakdown of common materials and their uses:

| Raw Material | Primary Nutrient | Commonly Used For |

|---|---|---|

| Corn / Maize | Energy | Poultry, Livestock |

| Soybean Meal | Protein | All Animals |

| Wheat Bran | Fiber | Cattle, Sheep |

| Alfalfa / Grass | Fiber, Vitamins | Rabbits, Cattle, Sheep |

| Fish Meal | Protein | Aquaculture, Piglets |

This flexibility7 empowers you to be a true nutritionist for your farm, adapting to changing seasons and animal needs.

What Are the Different Types of Feed Pellet Mills?

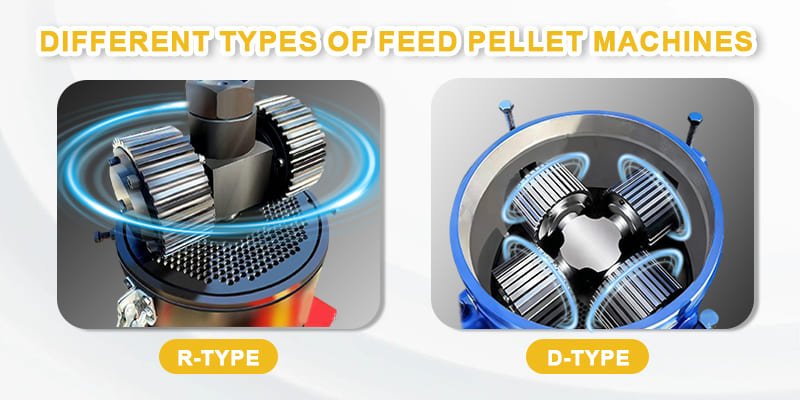

Confused by all the technical terms like 'D-type' and 'R-type'? Choosing the wrong machine type can lead to poor performance and damage. Let's simplify these options for you.

The main types are D-type (die-turning) and R-type (roller-turning). D-type is great for softer materials like grain and is more affordable. R-type provides more force, making it better for harder, fibrous materials. Power options include electric, diesel, and PTO.

Choosing the right type of machine is the most critical technical decision you will make. It comes down to two things: your raw materials2 and your power source3. As a manufacturer, we offer all these options because we know that a one-size-fits-all approach doesn't work in agriculture. A procurement manager for a brand must get this right to avoid costly returns and warranty claims.

Drive Type: D-Type vs. R-Type

The main difference is what part moves.

- D-Type (Die-Turning): The flat die with holes in it spins. The rollers are stationary and press the material through the spinning holes. These are excellent for soft materials like soybean meal, corn, and wheat. They are generally more affordable and are our best-sellers for poultry and pig farms.

- R-Type (Roller-Turning): The rollers spin, and the die is stationary. This design generates more pressure and is better for processing harder or more fibrous materials like grass, alfalfa, and straw. If your formula includes a lot of forage, this is the type you need.

Power Source: Electric, Diesel, or PTO

Your location and infrastructure will determine your best power option.

- Electric Motor: The most common and efficient choice if you have reliable electricity. They are quiet, easy to maintain, and cost-effective to run.

- Diesel Engine: The perfect solution for off-grid or remote areas where electricity is unstable or unavailable. A client in a rural part of Iraq chose this option for his cooperative, giving them total independence.

- PTO (Power Take-Off): This type connects directly to your tractor's PTO shaft, using the tractor's engine for power. It's a great choice if you have a tractor and need a mobile solution you can use anywhere on your property.

| Mill Type | Best For | Power Options | Key Advantage |

|---|---|---|---|

| D-Type | Grains, soft materials (e.g., corn, soy) | Electric, Diesel | Cost-effective, great for simple formulas |

| R-Type | Hard, fibrous materials (e.g., grass) | Electric, Diesel | High pressure, more versatile for complex materials |

| PTO | Mobile on-farm use | Tractor PTO | Mobility, no separate engine needed |

How Can You Choose the Best Small Animal Feed Pellet Machine?

Afraid of making a bad investment? A wrong purchase leads to wasted money, production delays, and unhappy customers for your brand. We can guide you to make the right choice with confidence.

To choose the best mill, first define your capacity needs9 (kg/hour). Then, match the mill type (D-type or R-type) to your raw materials2. Finally, select a power source3 that is practical for your location. Always prioritize a supplier with a strong quality guarantee.

I've been in this business for 25 years, and I've seen what happens when people buy the wrong machine. It doesn't perform well, it breaks down, and it becomes a headache. Let's follow a simple, four-step process to ensure that never happens to you. This is the exact process I use when consulting with new clients, from individual farmers to large buyers in the US and Germany.

Step 1: Assess Your Capacity Needs

How much feed do you need per day? Be realistic. Calculate your daily requirement and multiply it by the number of feeding times. Then, decide how many hours you want to run the machine each day. This will give you your target capacity in kg/hour. Buying a machine that is too small will create a bottleneck, while one that is too big is a waste of capital.

Step 2: Analyze Your Raw Materials

As we discussed, this is crucial. Make a list of your primary ingredients. If your mix is mostly grains and meals, a D-type mill is likely your most cost-effective solution. If you plan to use a lot of grass, hay, or other fibers, you will need the extra power of an R-type mill.

Step 3: Select the Right Power Source

Look at your farm's infrastructure. Do you have stable, three-phase electricity near where you'll be working? If so, an electric motor is your best bet. If you're in an area with unreliable power or need to move the machine around a large property, a diesel or PTO model will give you the flexibility7 you need.

Step 4: Verify Supplier Quality

This last step protects your investment. Don't just look at the price. Ask about the materials used for the key components—the roller and die should be made of heat-treated alloy steel. Ask about their quality control process10 and certifications like ISO 9001. A good supplier will be transparent and proud of their quality standards.

How Do We Ensure the Quality of Our Small Feed Pellet Making Machines?

Worried about machine breakdowns and a lack of support? A cheap, unreliable machine costs more in the long run through downtime and repairs. We build our machines for durability and performance.

We guarantee quality through a strict, multi-step process. This includes using certified high-grade steel, precision manufacturing, and having experienced QC staff on every line. Each machine undergoes load, efficiency, and durability tests before shipping to meet CE and ISO 9001 standards11.

As an OEM/ODM partner to global brands, we know that your reputation is on the line with every machine you sell. That is why our entire process is built around quality and reliability. For a procurement manager, choosing us means reducing risk and lowering long-term costs. We don't just assemble parts; we engineer solutions. Our 25 years of experience have taught us that quality isn't just one step; it's the entire system.

Raw Material Inspection

It all starts with the materials. We only use high-quality steel and cast iron that has passed our rigorous quality tests. Key wear parts like the flat die and rollers are forged from premium alloy steel and undergo a specialized heat treatment process. This ensures they can withstand the immense pressure and abrasion, giving them a service life of over 8,000 hours.

Precision Manufacturing & QC

Our five dedicated production lines are staffed by technicians with years of experience. More importantly, each line has a dedicated Quality Control officer with over 8 years of specific farm machinery manufacturing experience. They monitor every stage, from welding to final assembly, ensuring every component meets our strict tolerances and ISO 9001 standards11.

Rigorous Triple-Testing Protocol

Every single machine model we produce is subjected to a triple-threat test for power, efficiency, and durability. We confirm that it can handle its rated load, that its performance leads to a 30% increase in work efficiency, and that it lives up to our promise of durability. This is how we prove our designs and build trust.

Final Pre-Shipment Checks

Before any machine leaves our factory, it undergoes a full-function test under load. We check for vibrations, test performance, and ensure all systems are working perfectly. We then perform a final random inspection based on the ISO 2859 standard. Only after passing all these checks is a machine cleared for shipment to our partners in over 20 countries.

Conclusion

Choosing the right feed pellet mill gives you control and boosts efficiency. By focusing on your specific needs and prioritizing a quality manufacturer, you secure a reliable solution for your business.

Explore this link to find the ideal small feed pellet mill tailored to your specific farming needs. ↩

Discover the variety of raw materials suitable for feed production and their benefits. ↩

Learn about the various power options for feed mills and how to choose the right one. ↩

Discover how manual feed preparations can hinder your farm's growth and how automation can help. ↩

Find resources on formulating custom feed to ensure optimal nutrition for your livestock. ↩

Understand the importance of controlling nutritional content for animal health and growth. ↩

Discover the importance of flexibility in feed mills to adapt to changing ingredient needs. ↩

Understand the significance of using high-strength materials in feed mill construction. ↩

Find guidance on determining your feed production capacity to select the right mill. ↩

Understand the quality control measures that ensure the performance and durability of feed mills. ↩

Explore the significance of ISO 9001 standards in ensuring quality in manufacturing processes. ↩